On Its Journey To Make Clothing That Leaves No Trace, The North ...

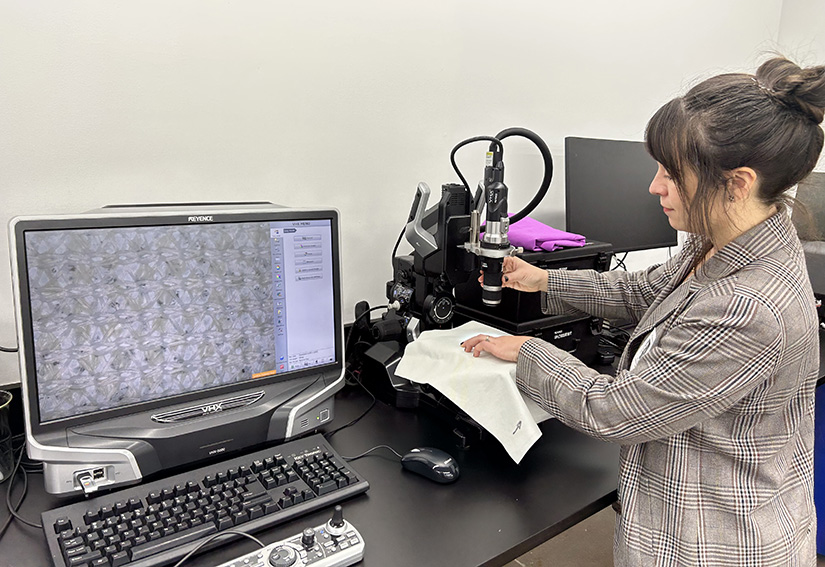

NREL Scientist Kat Knauer examines a weave of a novel biobased textiles using optical microscopy at The North Face’s Denver, Colorado, laboratories. Photo by Julie Thompson

When worn, washed, and dried, clothing sheds—dispersing tiny fibers throughout homes, soils, and waterways that can take centuries to degrade.

These fibers, often made of polyester and often too small to see, are a major—if invisible—source of microplastic pollution. By some estimates, fibers from polyester clothing account for nearly half of all microplastics in the natural environment, exacerbating a growing environmental and public health hazard.

Preventing clothes from shedding may be impractical, if not impossible. But according to National Renewable Energy Laboratory (NREL) polymer scientist Katrina Knauer, a better solution is emerging that could address the challenge at its source: replace today’s petroleum-derived polyester with a nontoxic, biodegradable alternative made from PHAs, short for “polyhydroxyalkanoates.”

“PHAs have been found to be very compatible with tissues in the human body as therapeutics,” said Knauer, who is the chief technology officer of the U.S. Department of Energy’s Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment (BOTTLE) consortium. “PHAs can also break down naturally without a highly controlled, composting environment.”

Already, BOTTLE scientists—including a team from NREL and Colorado State University—have developed a portfolio of PHAs with different properties, including some that behave like conventional polyester but are biobased, biodegradable, and easier to recycle.

Now, in conjunction with The North Face, that team is bringing those sustainable materials into the outdoor apparel industry. Over the next 12 months, BOTTLE will scale the process to produce several pounds of PHA fiber, which The North Face will test and evaluate for use in its product lines.

BOTTLE Tailors PHAs for TextilesJust a few years ago, research was inconclusive on whether making textiles from PHA was possible. Early production methods worked by extracting PHA from a bacterial synthesis, many of which naturally produce the polymer as they digest plant-derived products like glucose and fatty acids. However noteworthy at the time, that method made it difficult for scientists to control the resulting backbone and properties of the PHA.

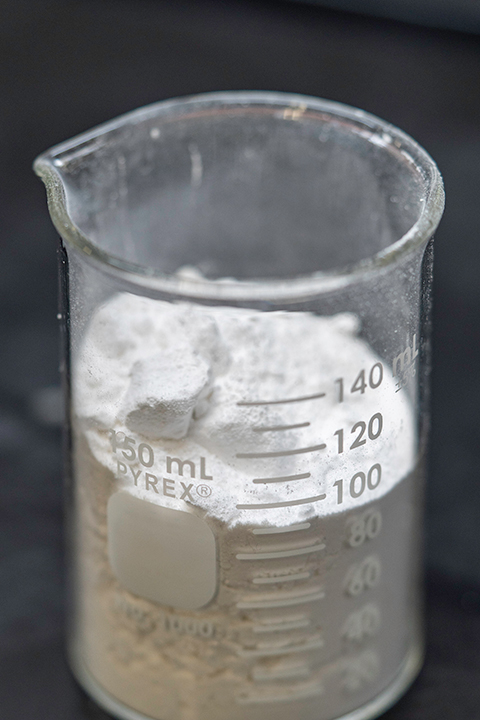

BOTTLE has tailored the chemical backbone of PHA—shown here before being spun into fiber—to increase its mechanical toughness and make it chemically recyclable. Photo by Werner Slocum, NREL

As part of their mission to create more sustainable plastics, BOTTLE scientists have since developed alternative techniques for turning succinic acid (made from glucose), and other biobased building blocks, into PHA via synthetic routes. Chemo-catalytic approaches allow the team to tailor PHA’s chemical backbone to achieve key attributes, like melt-processability, crystallinity, and ductility. With the support of the U.S. Department of Energy’s Bioenergy Technologies Office and Advanced Materials & Manufacturing Technologies Office, BOTTLE has reported PHA prototypes with a broad range of properties—from rigid PHA polymers for clear food packaging to ductile varieties for spinning into fiber.

“We’re actually showing we can control the microstructure to get PHA to behave like polyester fibers and textiles,” Knauer said.

Unlike conventional polyester—a petroleum-based textile that constitutes more than half of fabrics produced annually—BOTTLE PHAs are also designed for recycling. At the end of a product’s useful life, BOTTLE’s chemical recycling technologies can deconstruct PHAs and other polymers back into chemical building blocks pure enough to reuse for making plastics of the highest quality.

According to Ravikumar Gowda, a BOTTLE researcher based at Colorado State University, the material’s recyclability hinges on specific changes to PHA’s chemical backbone. By replacing reactive hydrogen atoms with robust alkyl groups, Gowda and other CSU researchers significantly enhanced the thermal stability of PHA to make it melt processable—a key advantage over PHAs derived from microbes. Importantly, the change also enables the team to deconstruct the polymer at will.

“Our redesigned PHA structure substantially increases mechanical toughness and renders the new PHA chemically recyclable to its building-block monomer with a simple catalyst and heat,” he said. “The recovered monomer can be reused to reproduce the same PHA again, in principle, infinitely.”

Toward a Better Clothing IndustryBOTTLE’s work with The North Face comes as concern is rising on the environmental footprint of making and wearing clothing. The textile production supply chain accounts for an estimated 8%–10% of global carbon dioxide emissions.

For this reason, the project prioritizes analysis to understand the energy and carbon intensity of making and recycling PHA fibers. The team will also simulate microfiber shedding and measure their rate of biodegradation in a variety of environmental scenarios. Together, these results will give The North Face a picture of PHA textile sustainability to compare to conventional polyester.

“We are committed to making the best-performing products while leaving an ever-smaller footprint on the planet,” said Carol Shu, senior manager for global sustainability at The North Face. “Materials innovation is a pinnacle of our brand, and this project not only brings to life new possibilities for synthetic textiles but also supports our focus on enabling product circularity.”

After reviewing BOTTLE’s initial results, The North Face aims to test prototype fibers with its suppliers to evaluate for a line of more-sustainable products.

For clothing that looks good, feels good, and performs in the most punishing outdoor conditions, the goal is to find the perfect PHA fiber to match, or even improve upon, the qualities consumers value most. Best of all, it should enable adventurers to scale mountains, run trails, and explore cities with the confidence they will leave no trace of microplastics in the process.

Learn more about the BOTTLE Consortium and NREL’s bioenergy research.